Why Tofu Cat Litter Is the Future Trend of Pet Products?

As global pet owners become increasingly environmentally conscious, tofu cat litter is rapidly replacing traditional bentonite cat litter and silica cat litter.

Global Market Trends:

Sustainable and biodegradable materials

Low dust, safer for cats and households

Flushable and easy disposal

Low carbon footprint with renewable raw materials

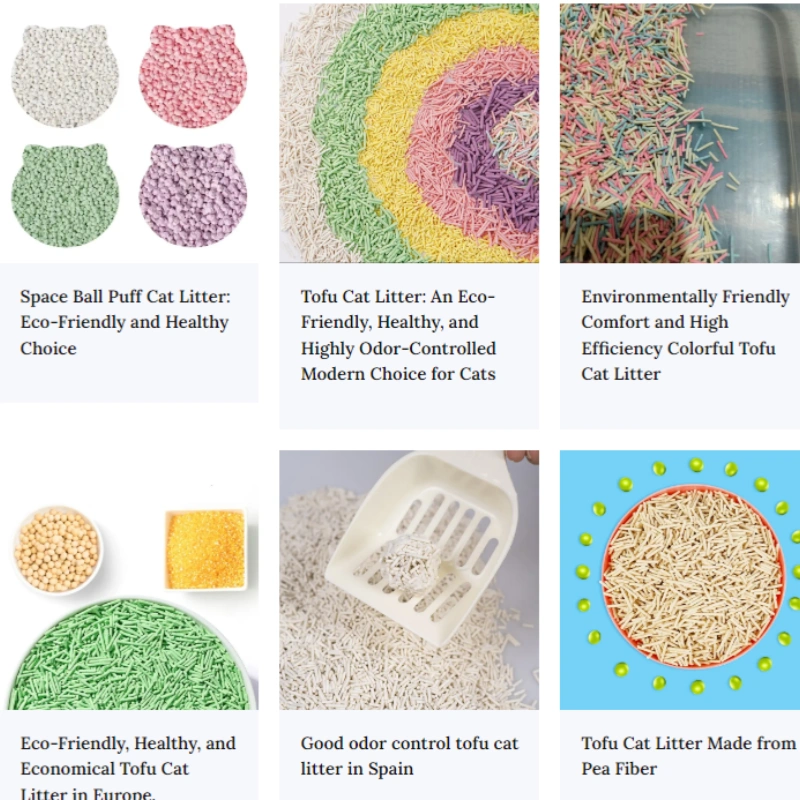

Tofu cat litter is mainly made from plant-based ingredients such as pea fiber, soy fiber, and corn starch. These materials are safe, eco-friendly, naturally biodegradable, and suitable for long-term household use.

Factory Strength Overview

Shandong Gelin Town Pet Products Co., Ltd. is a professional tofu cat litter manufacturing factory equipped with modern fully automated production lines and operating under a strict quality management system.

Factory Advantages:

Annual production capacity: 7,000+ tons

Fully automated extrusion and drying production lines

Stable raw material supply system

In-house R&D and formulation team

OEM / ODM customization capabilities

International certifications: ISO9001, SGS, CTI

From raw material selection to final packaging and shipment, we maintain full-process in-house control to ensure consistent and stable quality for every batch.

Premium Raw Materials – Quality Starts from the Source

Unlike low-cost factories that use recycled materials or cheap binders, we insist on selecting high-grade plant fibers and food-grade binding ingredients to ensure product safety and performance.

Core Raw Materials:

Pea Fiber / Soy Fiber – Fast absorption and strong clumping performance

Corn Starch / Cassava Starch – Natural binding and biodegradable

Guar Gum – Strong clumping power without chemical adhesives

Natural Deodorizing Minerals – Long-lasting odor control

Food-Grade Fragrances (Optional) – Green tea, milk, lavender, activated carbon

We never use industrial glue or add harmful chemical substances, ensuring long-term safety for cats and households.

Advanced Manufacturing Process

Our production process is highly standardized and operates under digital monitoring to ensure consistent quality and efficiency.

Production Flow:

Raw material inspection and moisture control

Precise formula mixing and batching

High-temperature extrusion forming

Continuous low-temperature drying

Dust removal and sieving

Metal detection and quality inspection

Automatic weighing and packaging

This process ensures:

Uniform particle size

Fast and strong clumping performance

Extremely low dust level

High water absorption capacity

Stable storage and shelf life

This is an overall view of our factory. Covering a large area, the factory is equipped with multiple fully automated tofu cat litter production lines, with a total annual production capacity exceeding 7,000 tons, capable of reliably handling large-scale OEM orders and long-term cooperation projects.

The factory operates strictly under the ISO9001 quality management system, ensuring a clean, safe, and efficient production environment that meets international customer audit standards.

The production lines use high-temperature extrusion forming combined with a continuous low-temperature drying system, ensuring uniform particle size, stable moisture content, and strong clumping performance of the tofu cat litter.

The entire production line is fully automated, effectively reducing human errors and improving batch consistency, making it especially suitable for long-term, stable supply to export markets.

The automatic weighing and packaging system ensures precise weight for each bag and stable, secure sealing. It supports multiple packaging specifications:

2.5kg / 5kg / 7kg / 9kg / 10L / 20kg / jumbo bulk bags

Packaging options include PE bags, kraft paper bags, cartons, and OEM custom packaging.

Finished products are managed in unified batches and inventory control is implemented to ensure fast delivery and first-in, first-out (FIFO) management.

We support full-container and mixed-container exports, providing long-term, stable shipments to North America, Europe, South America, the Middle East, and other markets.

387.webp)

122.webp)